January 15th 2020 LH454 took me from Frankfurt to San Francisco. I got a rental car and drove to a descent motel, a few miles north of Richmond.

It was cold and rainy. The four hour drive to Corning was boring. 5581M was exactly as I left her three months ago, patiantly waiting for me in the rented hangar:

As it was getting late that day, I continued to Red Bluff, where I would stay the next days. Some packages were already waiting for me:

The packages contained parts and tools for the planned repairs, maintenance and upgrades. At the Red Bluff airport, I met my mechanic Randy, discussed the planned work with him, drove back to Corning, flew 5581M over to Red Bluff, put her in Randy's hangar, took an Uber back to Corning and drove my rental car to Red Bluff. Enough for the day, as jetlag is taking its toll. Let the work begin tomorrow...

I had to remove ice on the windows of my rented car, before I could drive to Red Bluff airport. My clothing was optimized for the tropics, I was freezing in the hangar, when I arrived there at 7 AM. Under the supervision of my A&P I removed the old ELT and replaced it by a new one. Then we removed the turn- and bank indicator and the old mechanic clock - both optional equipment. We discussed, where to install the new EFIS and the new analogue Voltmeter. 10 hours went by quickly, we stopped work, when my headlight's batteries were depleted.

I began the work at 7 AM in Randy's hangar in Red Bluff, but at 10 AM we flew 5581M over to his own airport. There we began the extended annual.

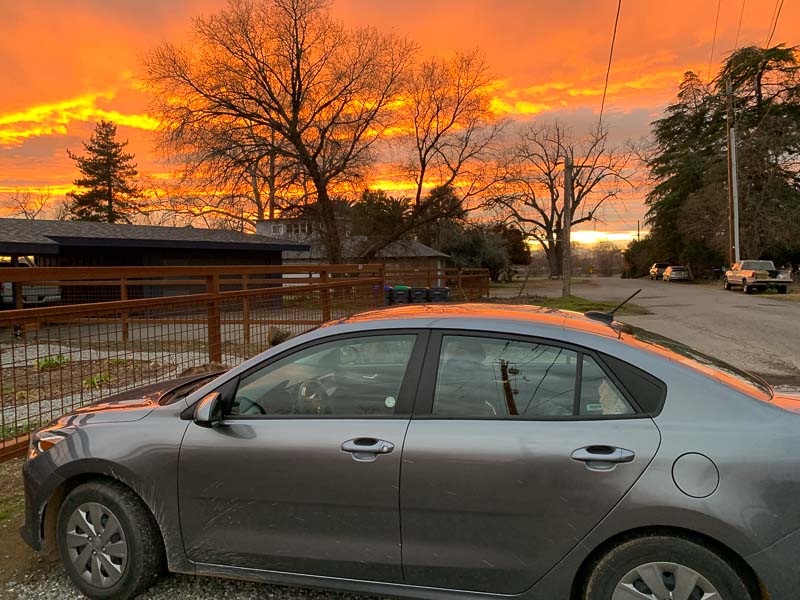

Most of the day I troubleshooted 5581M's electric system. It is not complicated. In fact, it is a very, very simple system. But this doesn't mean, it is easy to understand. It is old. Apparently, nobody ever re-wired the aircraft completely. At least not since 1983, when the aircraft was reassembled after being stored for 11 years. But I believe, many wires date back from 1947, when the aircraft was produced. There is no color coding. There are dead wires. There is no documentation and no visible philosophy being followed. Space under the dashboard is crowded. Lighting is poor. It is hard to follow the wires. It is hard to measure resistance and voltages. After some hours, I identified problems in the wiring leading to the landing light in the left wing. We opened it and found issues. We fabricated new wires. Hopefully, the problem is solved. In the evening, we enjoyed a beautiful sunset:

We exchanged all three tires and tubes. The first of the two pictures above shows the tiny tail wheel, which - like the two bigger main wheels can be split into two parts to allow easy installation of tubes and tires. The second picture above shows the tailwheel's tube and tire.

What else did we do? We replaced the old 20A landing light by a new 2.6A LED light. What a relieve for the electrical system load! We finished the oil change by adding 5 qts Aeroshell 100 and did a test run of the engine. No issues here. We painted the left gear leg red for a first time. We installed a new but classical looking (analogue) voltmeter in the dashboard. We sand-cleaned the prop and polished it.

Today, we worked a lot on the avionics, installing the new pilot-side EFIS. It is not easy to install such a big device in the small 140 dashboard. The picture above shows the shop's large supply on fittings, but unfortunately we didn't find the ones we needed and had to buy new ones in order to connect pitot and static of the new multi-function instrument.

What else did we do? We sealed the top (skylight) windows with transparent silicone, because the roof of the cabin was leaking when it rained. We exchanged the battery master solenoid to fix an electrical issue. We partially primed and painted the left gear leg red a second time We exchanged the new ELT's remote control unit. We fabricated several electrical cables

Without pitot and static connected, the new pilot-side EFIS is basically just an artificial horizon.

We began to strip the paint strips from the fuselage. We did this to clear the ground for the large 12 inch registration markings, which are required for international flights.

We weighted the aircraft. The picture above shows the tail lifted. This is necessary for calculating the center of gravity. Then, the aircraft was flown from Randy's ranch back to Red Bluff

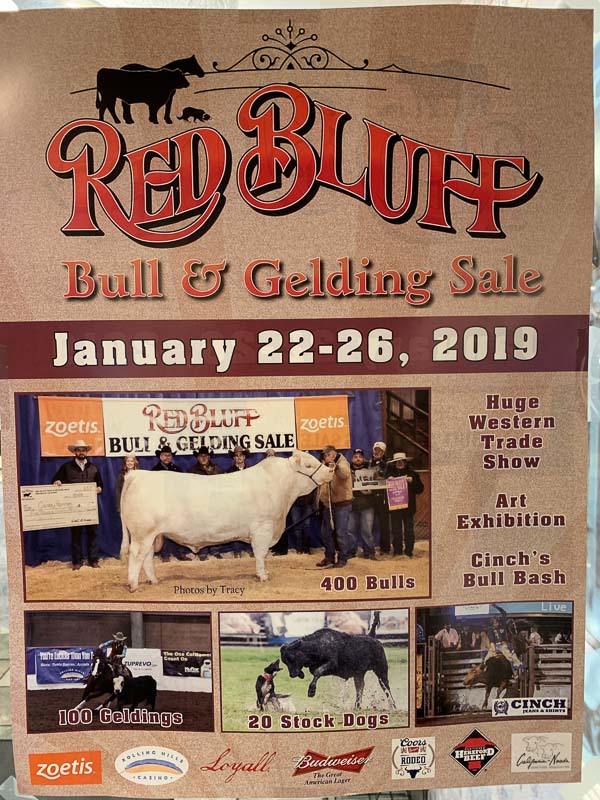

Suddenly, Red Bluff was full of men with cowboy hats. The annual "Bull & Gelding Sale" is a big thing for this small city. All the restaurants were full.

With 5581M airworthy and back in Red Bluff, we filled up all the tanks and I flew a few pattern.

Afterwards, I continued to strip down the pain.

5581M is now fully prepared for the long trip. I returned the rental car in Redding, took an Uber back to the Red Bluff airport and took off. The journey begins ...